I’m hoping to finish up the lids for the Zebrawood boxes this weekend and thought it might be a good idea to post on the previous work it took to get them to where they are now. I had chronicled the process on my facebook page some time ago, back when we were living in Albuquerque, NM. The unfinished boxes had been stored away in a box of several small projects that were in the works when we packed up to move to the Land of Frozen Tundra…or 10,000 Lakes as the locals like to call it. J

The following is a catch-up post to bring you up to date on the project. These boxes are a Doug Stowe design from his book, “Basic Box Making.” His design calls for decorative pegs or splines, however this Zebrawood has so much interest in the grain pattern I thought they might make them look too “busy.” I’ve got plans to do more of these boxes in Oak, where splines or pegs would really add something to the look and feel.

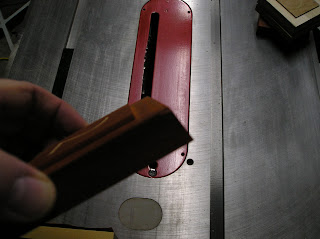

I took a lot of queues from Doug’s book. For those of you who’ve read it you’ll see several familiar things…starting with the miter sled for the table saw.

Each box side was cut to size with mitered corners on this new sled.

I invested a lot of time fine tuning both the sled and the saw settings which yielded some very nice results. Square corners are a thing of beauty…if that’s what you’re shooting for. (Note: Next time I use this sled I’ll probably have to make some tuning adjustments. There are some pretty big differences in temperature and humidity between New Mexico and Minnesota.)

After cutting all the side parts for four boxes, it was on to cutting the grooves to receive the box bottoms. It was critical to mark the pieces with an orientation mark and box number so that the grain pattern flowed around each corner.

Once the grooves were done I cut the box bottoms from quarter inch Baltic Birch plywood. This stuff is really nice to work with and will provide a very stable bottom for these boxes. After cutting the pieces to size I cut a rabbet around to bottom of each one, to fit them into the grooves on the side parts.

With all the work complete on the side pieces, it was time for some sanding. It’s much easier to sand the inside of a box before it’s a box, so I hit each part, front and back with my half-sheet pad sander. Doug Stowe inverts his on his bench and holds it down with a sand filled inner-tube. I built a wacky looking jig that can be clamped to the bench top.

Once all the parts were sanded and cleaned up, it was time to assemble the boxes. I used blue painter’s tape to line up each part and fasten them into a row. The key is to line them up as straight as possible and to apply the tape with a taut springiness at each corner. I like using this tape as it holds really well and has a slight stretchy quality.

With all four boxes taped up and ready to go it was time to apply the wood glue. The small applicator bottle with needle is another Doug Stowe recommendation that I adopted.

It was then time to insert the bottoms and “roll” each piece up. You’re looking for a hint of tension at each corner as you pull it all together. This ensures you’ve got a tight fit.

When all four sides have been rolled together some more tape at the closing corner holds the whole box together while the glue dries.

Once the glue had set, it was time to peel all the tape away and clean each box up on the sander.

Then you can pack them in a box, move across the country, pull them out a year later, and then finish them up. I don’t know why, but Doug failed to include this step in his book.

Pete