With a premise of using as much salvaged material as

possible I started this art piece almost two months ago. I worked on it a little at a time…sometimes

from a timing perspective and sometimes from a process perspective.

The salvaged materials are all from previous projects around

the shop…pegboard, 2X4 scraps, plywood and even some acrylic paints. The only purchased materials were the cans of

spray paint. Even the plastic drop cloth

used to protect the bench was reused. Of

course there were some of the standard consumables that were already in the

shop…tape, glue, wall anchors and screws…I did reuse a handful of old sandpaper

scraps though.

The base parts of the piece are the pegboard and thin strips

of 2X4 stock. I jointed and planed the

faces and edges of a couple 2X4 scraps and then ripped them down to these

strips on the table saw.

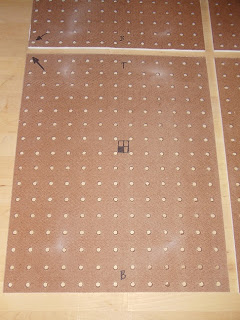

After cutting the pegboard panels to size and priming the

faces, I laid out the positioning of each of the four pieces and marked the

backs for future reference.

Since the painted

pattern and the position of the strips will rely on the placement of each piece

to maintain continuity I didn’t want to take any chances on me remembering

which piece went where…or which way was right-side up…or upside-down…or, well

you get the picture, and some of you have been down this same road!

I had toyed with the idea of leaving the wood strips their

natural color, and I may do another piece with that tact, however I opted to

use some colored stain to present more energy and contrast. A quick trip to Home Depot revealed that

small cans of colored stain could be had for $12 each…what!? A quick trip back home and a few minutes on

Google revealed that I could make my own with watered down acrylic paints. So in the interest of using materials on hand…OK,

you got me, I’m cheap! The process was

actually pretty easy, and the wood took the stain quite well.

When the piece is hanging on the wall I wanted a one and a

half inch gap between the panels on all sides.

I laid out my four parts, on a plastic drop cloth, with two scraps of

3/4 inch plywood between each panel to aid in placing the pieces.

Once I was happy with the placement I taped the parts down

to hold their position on the bench top.

With all of the parts secured, it was time to start getting “artsy.”

One of the processes that made this project take extra time

was the painting. Because I wanted

triangular forms with crisp edges only a couple of areas could be painted at

any one time.

With each section I would remove the tape edges and paper

about 10-15 minutes after spraying and then leave the piece to set up for a day

or two. Because I would have to tape out

subsequent sections over areas that had already been painted I wanted to be

sure the spray paint was cured and hardened.

Once all of the sections had been painted it was time to add

the layer of the wood strips. I wanted

the strips to traverse across two, or even three, panels in some places, and I

wanted to highlight as many of the knots as I could to emphasize that this was

another material layer.

You can now see the critical role that taping the panels

into place plays in the design. Once I

was satisfied with the location of each strip I marked their locations with

some blue painters tape. I oriented the

tape to indicate the direction of each piece and marked it with each piece’s

color and whether it was laid under or over any adjoining strips.

My lovely bride snapped a photo of me explaining the layout. I have to confess I was so “into my own thing”

that I didn’t even notice this was taken until she showed me. J

Just before moving on to attaching the strips to the panels

I had the thought that this spray paint is pretty slick (Duh!) and that the

glue I was planning on using probably wouldn’t fare too well. I decided to conduct a little test first…gory

details here - http://secondwindworkshop.blogspot.com/2012/10/testing-titebond-321.html

At the end the day there was no way around it…some sanding

would be required! Using the tape layout

pieces as a guide I sanded away the top of the paint layer to create a better

gluing surface.

The placement of the strips was another time consuming

process as only one or two could be done at a time. The weapons of choice…some plywood scraps and

a whole lot of weight.

With all of the strips in place I could now remove the

panels from the bench top and trim all of the overhanging pieces. My little Japanese Dozuki was just the

ticket.

The drop cloth actually looked a little “artsy” in its own

right.

It did go on to serve another purpose though, as a layout

guide for where to place the wall anchors.

I decided to hang these panels using French cleats. I attached the cleats at the top side of each

panel and added a little offset strip at the bottom.

Because the positioning of each panel, in relation to the

others, is so critical I used wider cleats to allow for some side to side play,

and cut these vertical slots into each one to accommodate any adjustments up or

down that might be needed.

All in all, I’m pleased with the piece. I think having it take so long (more from

having a day job than anything else) had me “getting used to it” if that makes

any sense. There were many lessons

learned along the way and I could point out all kinds of things I would do

differently or challenges I ran into that required some kind of fix, however,

in the words of woodworking great, Jim Heavey, I’m just going to “shut up.”

Pete